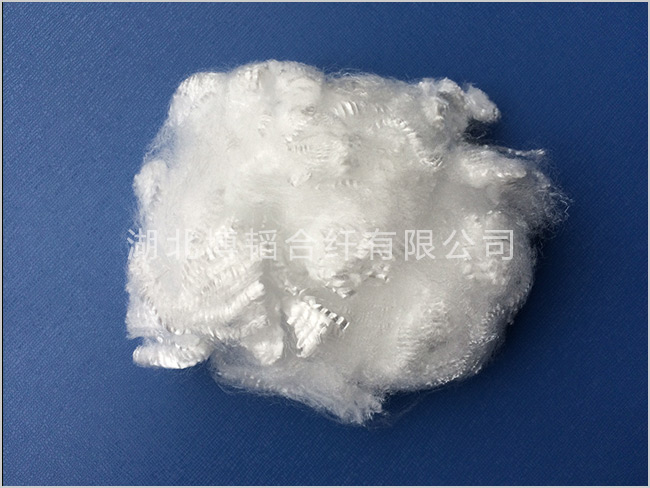

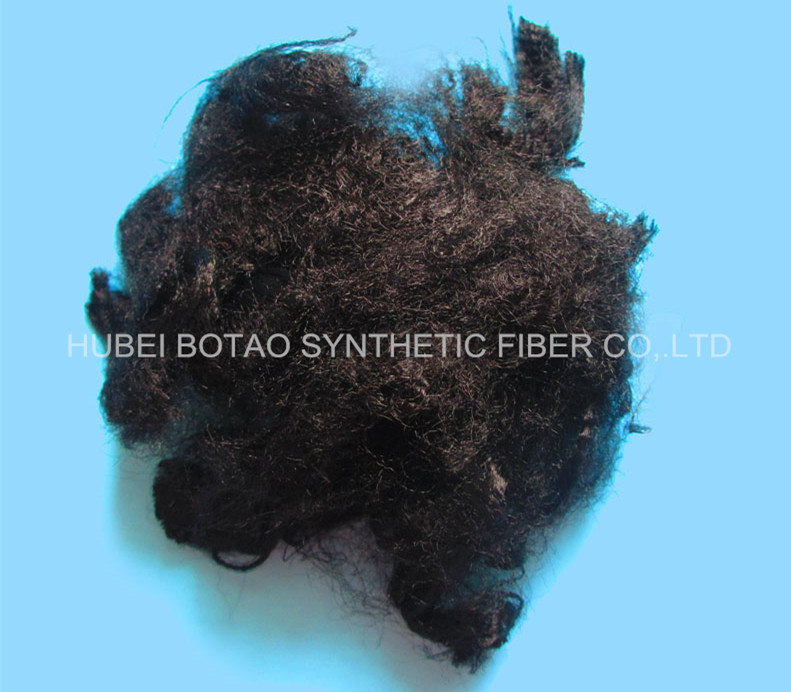

PP staple fiber for automotive interior

With the rapid development of automotive industry, the demand of automotive interior material is more and more. Due to density 0.91g/cm3, with the same weight PP fiber has larger covering area compared with other fibers, no wonder it is the perfect material for automotive interiors. In strict accordance with automotive industries'demand, our company, as a specialist in manufacturing PP staple fibers for automotive interiors with little odor, low VOC, low shrinkage, are the matching fiber supplier of GM,VW,TOYOTA and other main assembly plants. Our fibers have passed the professional inspections. Main specification: 6-22D×51-102mm white or black, other special standards also can be made to order.

Inquire Now Contact UsProduct Description

Polypropylene fiber, also known as PP fiber. Polypropylene staple fiber is made by high quality polypropylene through one step spinning process. Began in 1957, with the rich source of raw material, low price, simple production process, PP fiber is a cheaper synthetic fiber currently. Polypropylene fiber has good performance, rapid development and high output in the world, which is only after polyester fiber, nylon fiber and acrylic fiber.

PP staple fiber for automotive interior high elongation polypropylene fiber

Characteristics and Usage

Relative density: polypropylene fiber is light fiber of synthetic fibres, which density is about 0.91g/cm3.So the unit weight of the fiber can cover larger area.

Strength: The strength of polypropylene fiber is similar to that of high strength synthetic fibers like polyester and nylon, but the strength does not change in the wet state, which is better than nylon.

Abrasion Resistance and Corrosion Resistance: the flat abrasion resistance of polypropylene is only lower than nylon in sygthetic fibers, but the flexing abrasion resistance is slight wakeness.the propylene staple fiber has a significant stability for inorganic acid, alkali.

Hygroscopicity and dyeing: Polypropylene fiber moisture regain is less than 0.03%, which ensure the small shrinkage of its fabric . Fine denier polypropylene fiber has a strong core suction effect. Poor dyeing fastness so that almost all ordinary dyes fail to dye it, so far most of the colored polypropylene fiber are procued by method of dying before spinning.

electric insulativity and warmth retention: Compared with other synthetic fibers, polypropylene fiber has perfect electric insulativity with resistivity (7x10Ω.cm) and fabric warmth retention with small thermal conductivity.But the disadvantage is easy to produce static electricity.

Heat resistance and Aging resistance: with low melting point,about 165~173℃, polypropylene fiber has poor light and heat stability. So polypropylene fiber also is wake in heat resistance, aging resistance and ironing. However, it can be improved by adding anti-aging masterbatch when spinning.

In addition, polypropylene fiber, like other synthetic fibers, is not easy to mold, rot and not afraid of moth.

Now, polypropylene staple fiber is widely used in geotextile, hygiene material, filter cloth, linning and other non-woven fabrics, automotive interior, spinning, carpet, building material, composite materials, filling material, heat & sound insulation, bag, felt, etc.

Hubei Botao Synthetic Fiber Co., Ltd focus on production and sale: polypropylene staple fiber | polyester staple fiber | polyethylene fiber | bi-component fiber | PLA fiber.

Related Products

Get a free product quote

Our staff will contact you as soon as possible. If you need other services, please call the service hotline: +86-0724-2211070